Go back

Downstream Processing

Duration

5 days

Format

offline

Price

$5,450

Locations

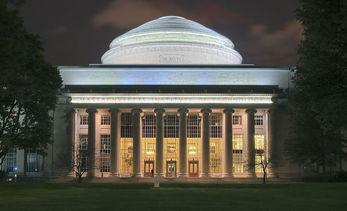

Cambridge, Massachusetts, United States

Date

July 20, 2026

MIT Professional Education

Want full info about Downstream Processing?

Detailed description and dates

Unbiased reviews from past participants

Global companies alumni of this course worked for

Positions of participants who took this course

Countries where most past participants are from

Bonus: Individual needs analysis